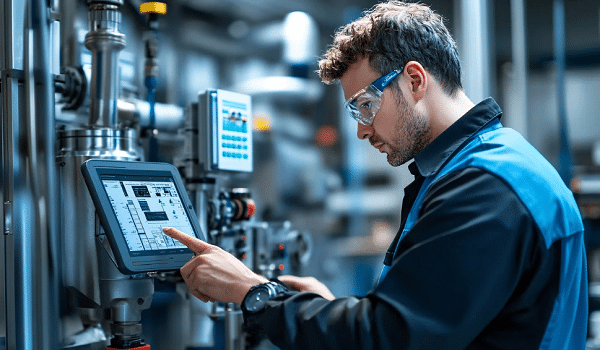

Digitalizing Production for Maximum Efficiency

The manufacturing industry is evolving rapidly, and digital transformation has become the backbone of efficient production.

By integrating IT systems into manufacturing operations—such as MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning), and IoT-enabled machinery—companies can achieve greater visibility, control, and coordination on the shop floor. Every component, from raw material tracking to final product delivery, becomes traceable and manageable in real time.

This not only minimizes downtime and waste but also ensures higher product quality and consistency.

With smart automation and data integration, manufacturers can respond faster to demand changes, optimize resource usage, and reduce operational costs.

Embracing digital production means staying competitive, agile, and ready for the future of industrial innovation.